Tin and red bronze (CuSn7Zn4Pb7, CuSn12, CuSn12Ni2, CuSn7Zn3Ni2PS,

CuSn12S) are copper-tin alloys with various additives. They provide excellent

wear resistance, corrosion resistance, and load-bearing capabilities. These

bronzes are widely used in mechanical engineering, particularly in producing

bearings, gears, and other components for demanding applications where

strength and durability are crucial. Tin and red bronze offer ideal solutions for

professional industrial use.

(CuSn7Zn4Pb7, CC493K, CuSn12, CC483K, CuSn12Ni2, CuSn7Zn3Ni2PS, CC471K, CuSn12S, CC472K)

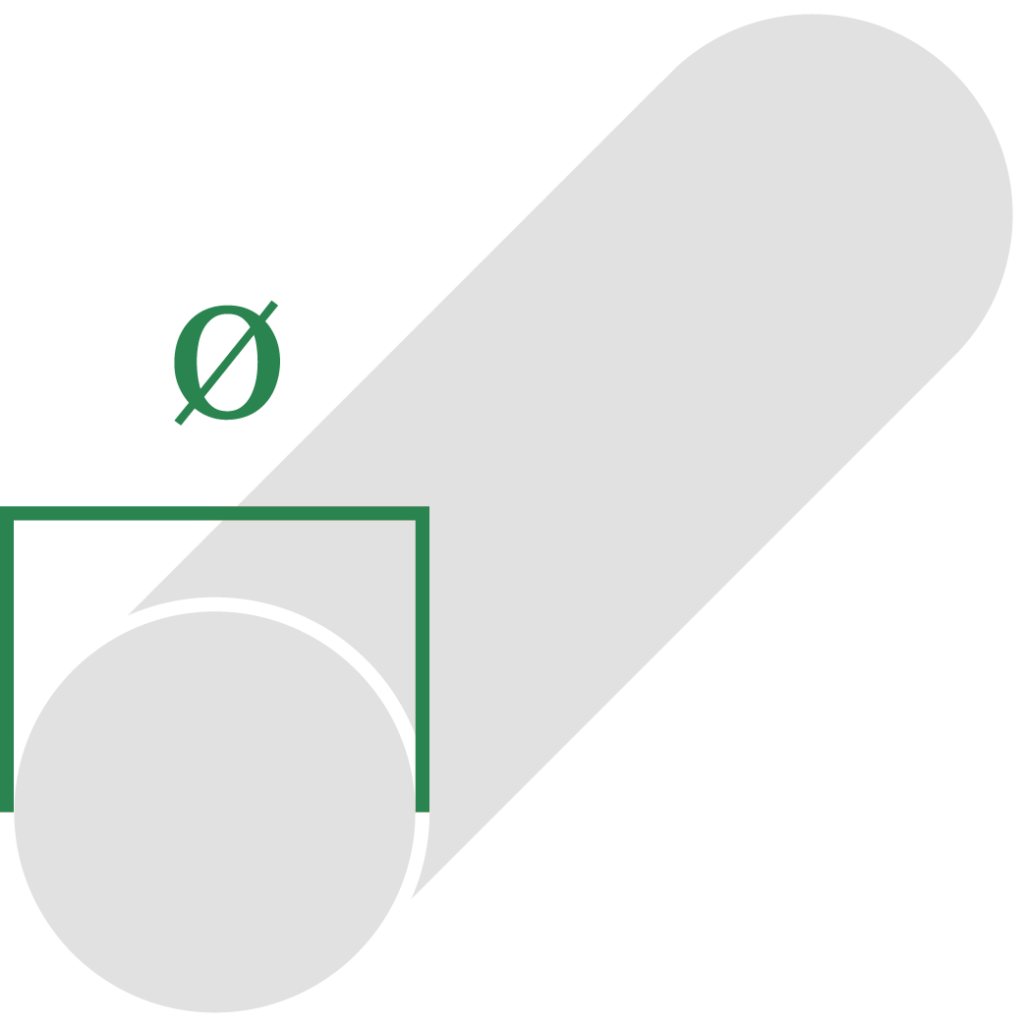

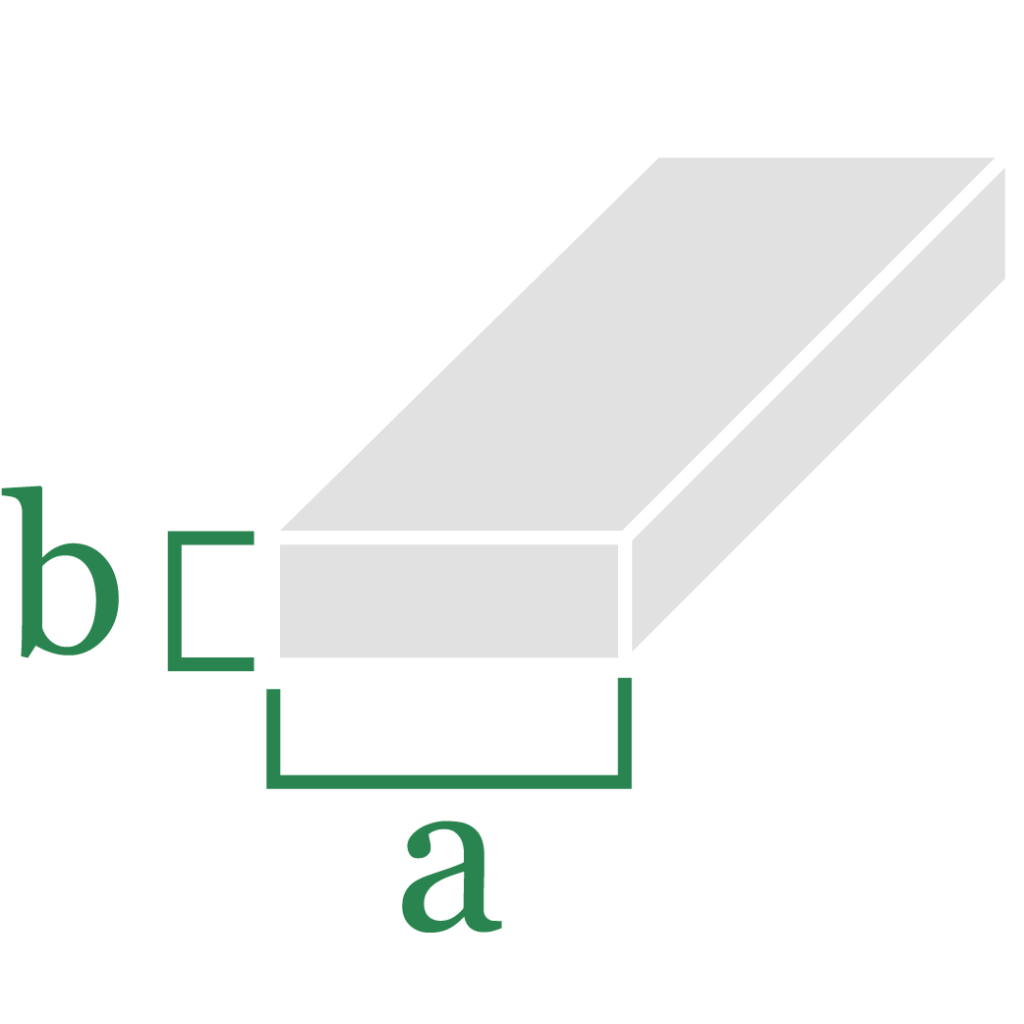

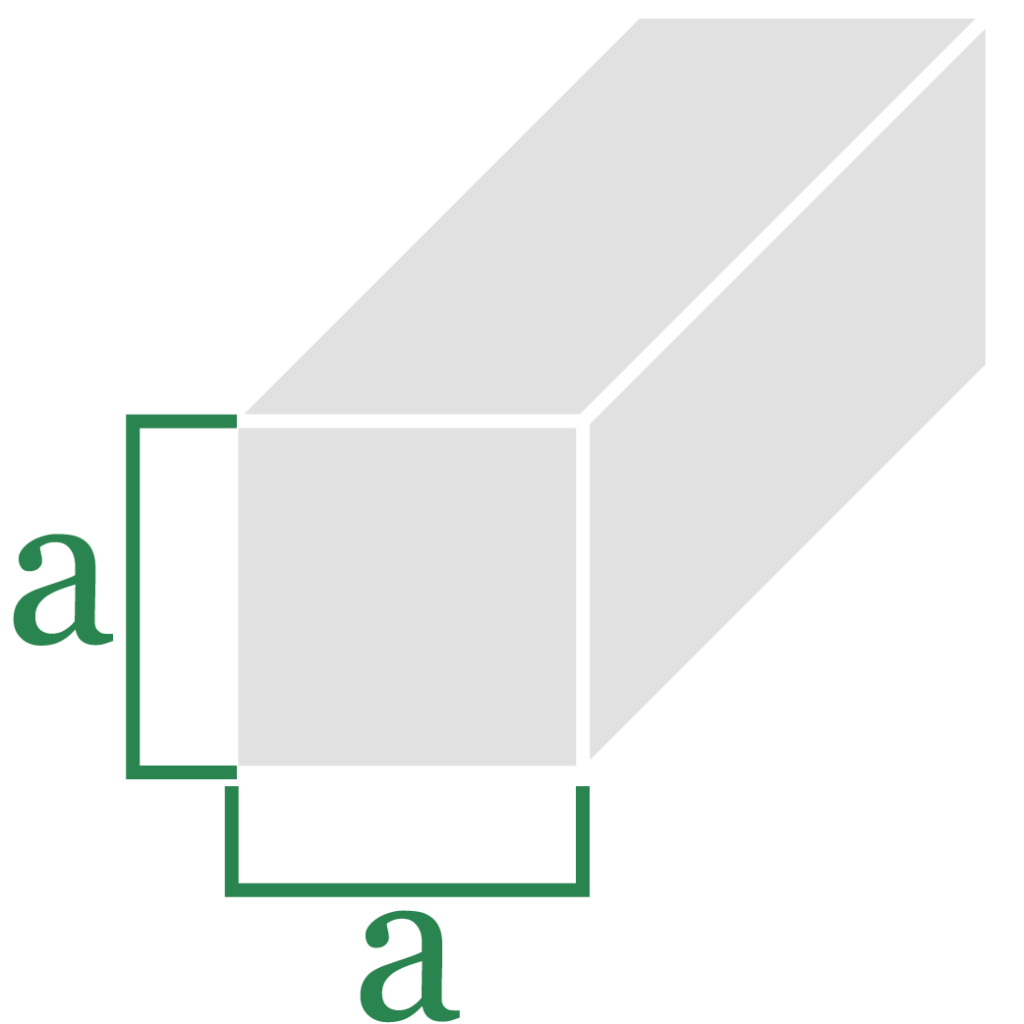

(CuSn7Zn4Pb7, CC493K, CuSn12, CC483K)

(CuSn7Zn4Pb7, CC493K, CuSn12, CC483K)

(CuSn7Zn4Pb7, CC493K, CuSn12, CC483K)

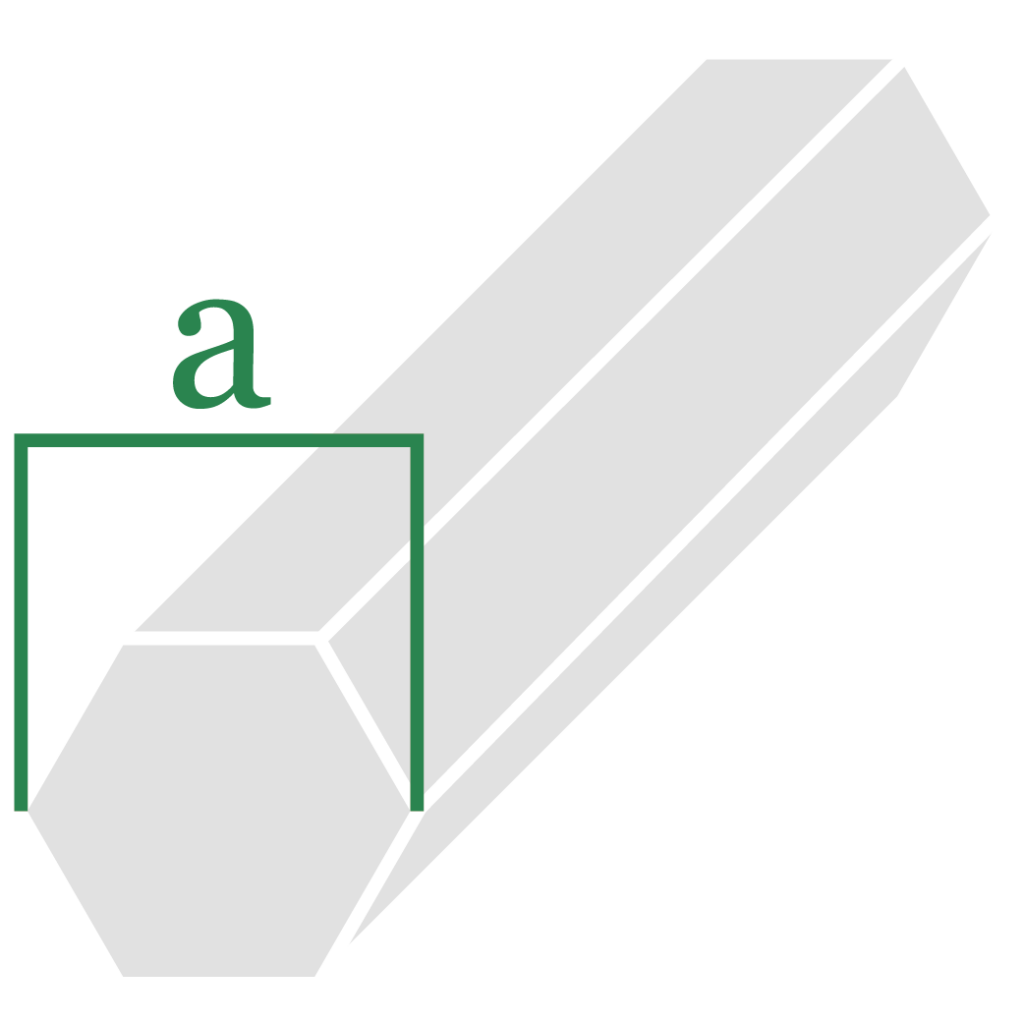

(CuSn7Zn4Pb7, CC493K, CuSn12, CC483K, CuSn7Zn3Ni2PS, CC471K, CuSn12S, CC472K)

Achieve more with our non-ferrous metals. Order today and start transforming your plans into reality.

The widest assortment of non-ferrous metals in Slovakia and Czechia, a modern 14,000 m2 facility, expert advice, material cutting to size and deliver within the entire EU since 1995.

© 2024 SERVISMETAL. All rights reserved. Created by Lemon Lion.